CLO 3D is now part of Blue Associates Sportswear.

3D design has been on the horizon for a couple of years now. Architects, Car Designers and Interior Designers have had the tools to create 3D designs to help present their concepts and now we have similar technology.

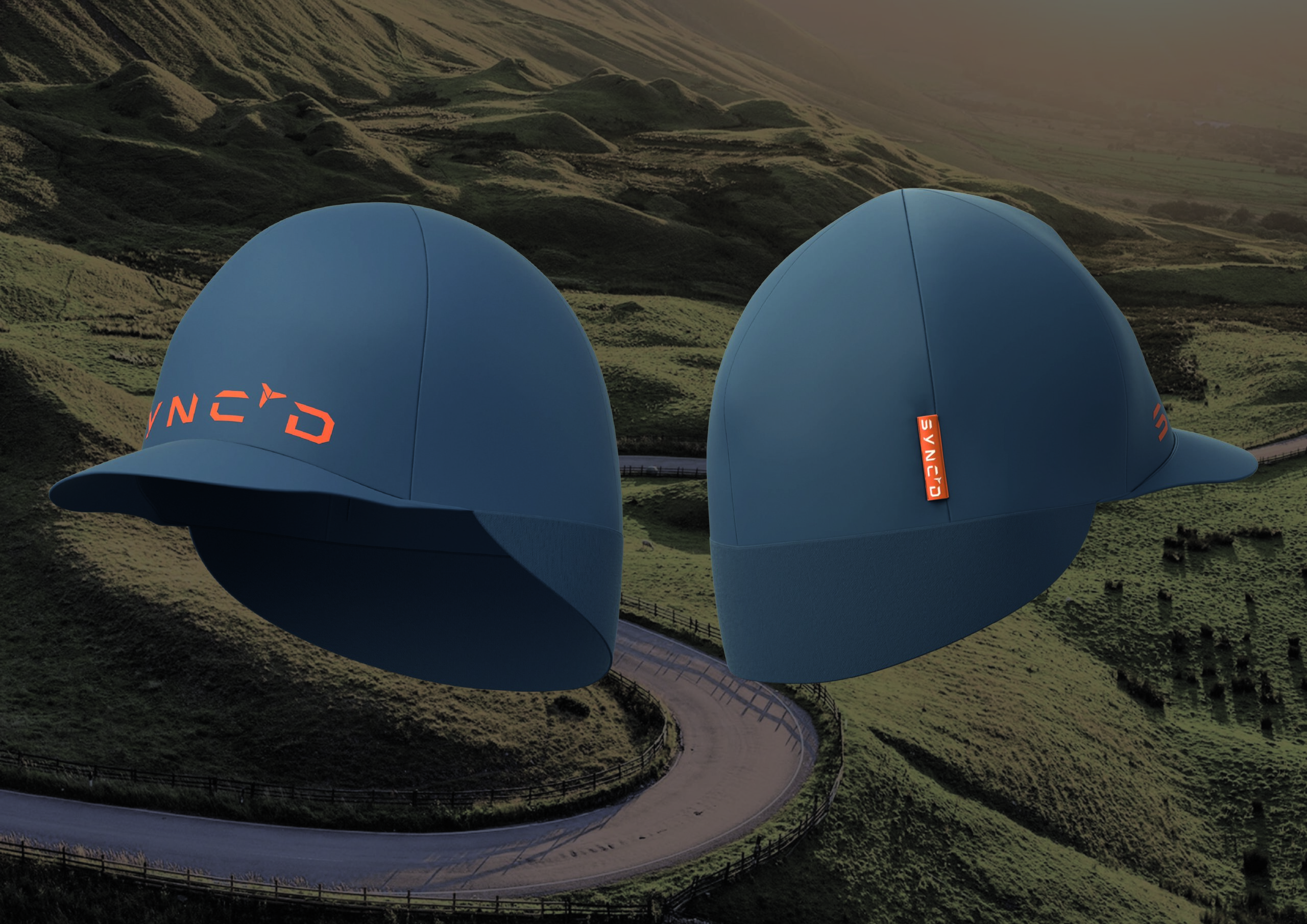

Clo3D enables us to create sportswear in a virtual 3D format by creating the designs around a prescribed avatar. This avatar can be manipulated in terms of gender, shape, size, race, and height and designs are created by cutting virtual patterns, stitching them and then placing them onto the avatar to create the 3D garment.

Fabric types can also be specified in terms of weave, knit, weight, structure, drape, sheen etc, and the clever software interprets this into a realistic 3D rendering. By a click of a button, we can see how alternative fabrics may look, hang, drape or if we want to adjust the fit, we simply nip and tuck the virtual garment until were all happy.

Impressive eh, but it doesn’t stop there. Not only can we now present much more realistic designs, but we should also be able to reduce the need for so many samples the factory need to produce, saving time, money and reducing carbon footprint.

Because the designs are incredibly realistic, this helps our clients sign off the designs with minimal changes down the line. It also represents a clearer vision of the finished garment to the factory, so they understand the fit, function and seaming/construction 360˚ around the garment. It gets better though, because the design is created by us cutting the patterns, the factory can take these patterns and utilise them when they produce the 1st prototypes.

The result is a far more accurate 1st sample that should represent the final fit far better than using 2D designs which hopefully reduces the sampling required before bulk production can start. With each sample round taking anywhere from 4-12 weeks and with associated factory sample fees, courier and duty charges, this should not only save valuable time but help the investment required in the development process too.

“WOW”, I hear you say, however it doesn’t stop there either. Some brands are now using these realistic 3D renderings to presell capsule collections with limited edition runs, reducing the need to purchase excess inventory by only ordering what they sold. This protects their brand values, maintains margins and stops waste.

If you are interested to find out more about 3D sportswear design, then please get in touch.